Awesome JBomb! Thanks. However, if that car is wider than 18mm, then it will be forever locked in the back yard!

FYI: There is already a Lamborghini drawn in the garage! HEH.

Sarge, the original home is in Madison, Wisconsin, and it gets pretty damn cold up there. But then again, this house had the world's first, steam-pipe heated concrete slab floor, and \"Thermopane\" (Plate glass), but yeah. that house wasn't particularly warm.

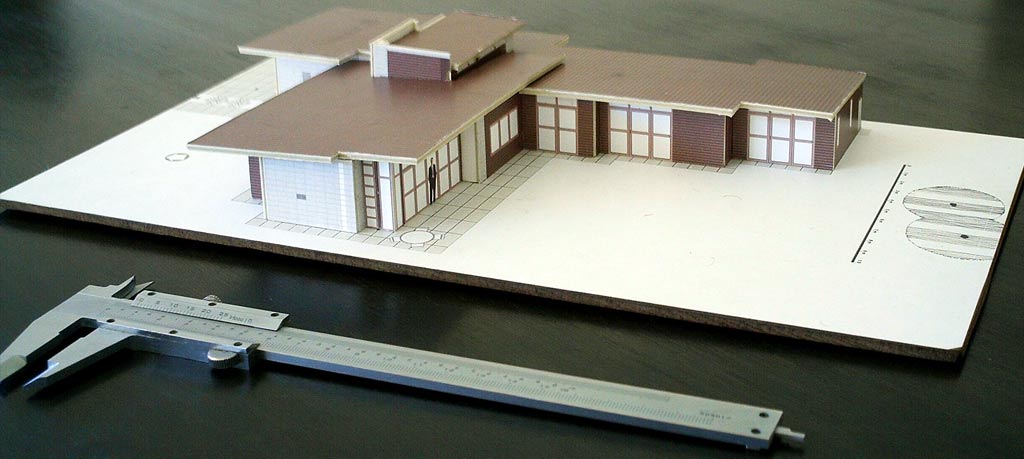

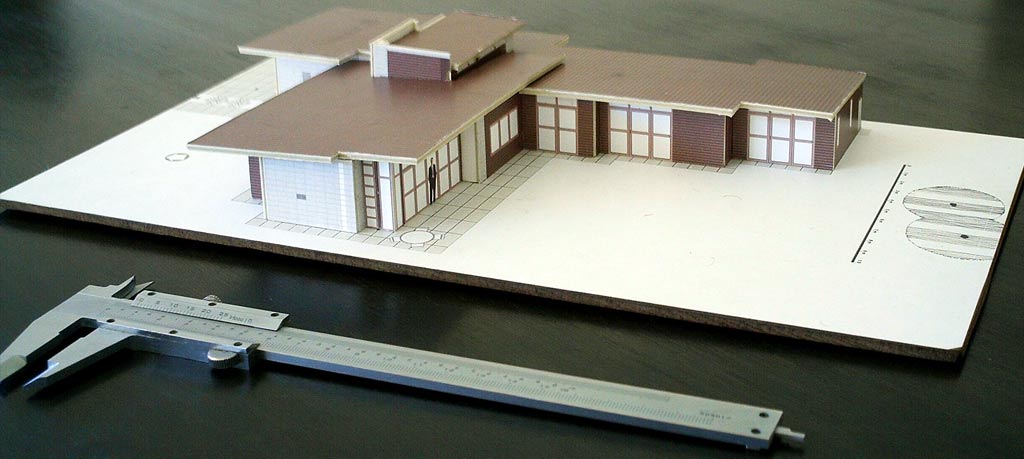

The rooves ARE removable: and inside, all the features and furniture is printed on the floor. The rooves have small carboard squares to locate them correctly onto the model, so that they do not fall off. The top roof is so finely built, that it is retained by pressure fit alone.

There's nothing difficult about making a model like this: any F00 can do it. (I mean, I did!) In Photoshop, I simply projected the plan lines, and all that was required was to make the heights of things correct. The 3 degree pitching is easy to calculate: SIN(3) * DISTANCE in metres = the height to increase over that distance.

Once the elevations were done, I simply added a few spare panels of onduline and concrete block, to make up for spaces where the elevations did not show parts of the model I'd need to build.

Had them printed out professionally at 118% of the size, to create a correct 1:100 model parts (That's the scale you can see next to the trees on the back lawn).

Used spray adhesive to glue the printed paper onto 2 thicknesses of cardboard, and then you are good to go. Just about wrecked my index finger having to press so hard making all the cuts - man the roof cardboard was like cutting concrete!